Automotive Displays Accomplish More with Less Wiring

Heavy and complex cables present a problem in today’s efficient vehicle designs. As more operational functions move to the screen, automotive display standards help streamline connectivity solutions.

Soon, nearly every new vehicle will include at least one screen. Cars built since May 1, 2018, for the North American market feature a mandatory backup camera system connected to a screen that displays a field of vision of at least 20 feet back and 10 feet wide behind the vehicle. In the U.K. and Europe, this rule went into effect in 2021, and many other countries and OEMs have already, or will soon, implement the lifesaving technology. As automotive safety, experience, and drivetrain functions become increasingly interconnected, the simple backup screen has expanded its view to manage a host of new functions.

In automotive backup systems, cameras and sensors positioned on the rear and sides of the vehicle are connected by high-speed cables to a screen display embedded into the dashboard. (Wireless connections are used in some models.) Automotive displays solely dedicated to the backup function activate only when the vehicle is in reverse. Smart displays with embedded chip touch-screen functionality are constantly lit. When these vehicles are not in reverse, the screen becomes a central control center for traffic and GPS information, infotainment, climate controls, and other functions. By 2026, 34.1% of new passenger vehicles are expected to have digital instrument clusters, and 41% of central stack displays will measure nine inches or larger.

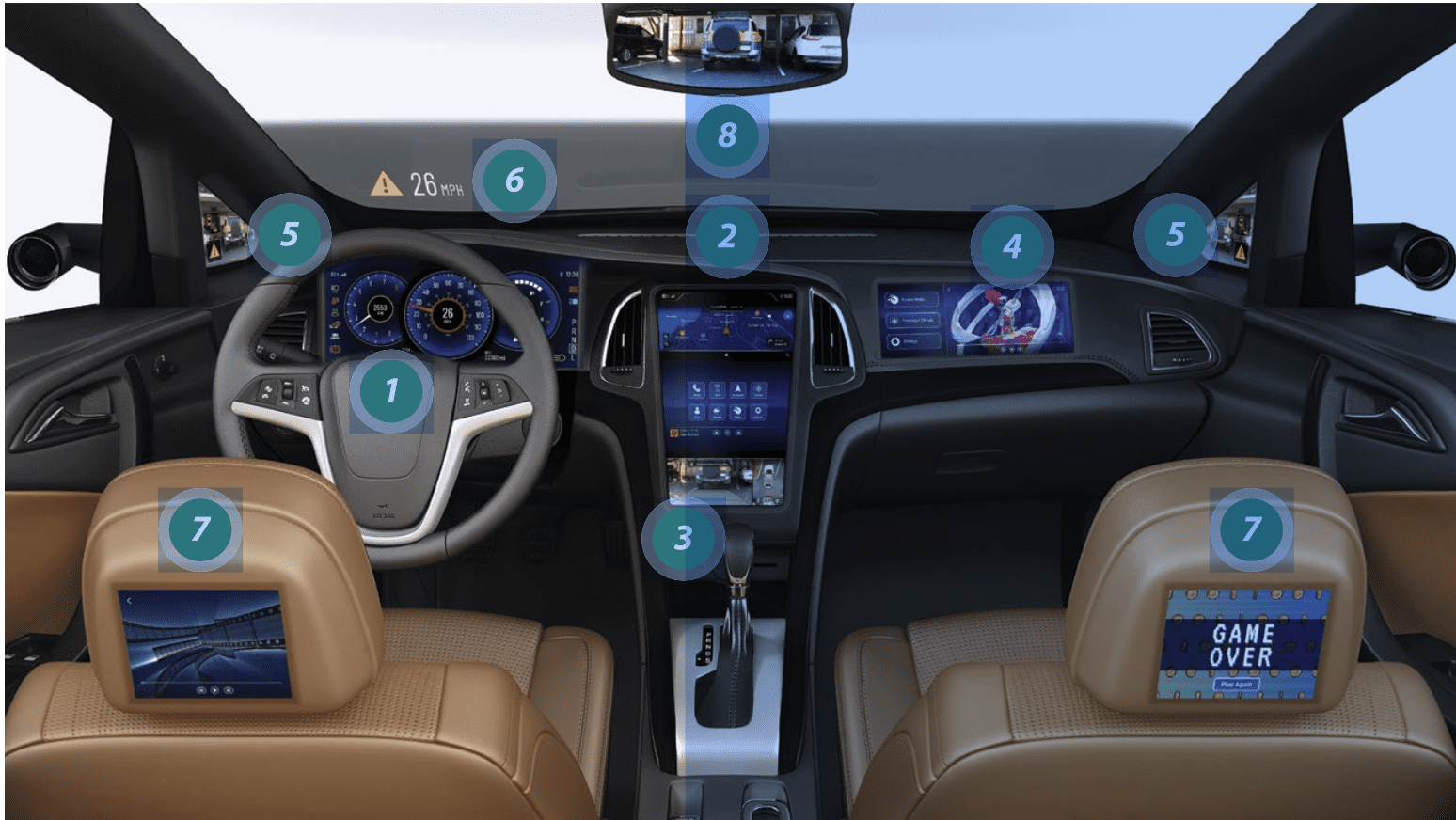

In addition to the required backup display, screens provide information and interactivity for numerous driver and passenger functions. (Image courtesy of the MIPI Alliance.)

To enable these high-function, high-resolution displays, multi-gigabit-per-second data streams must be transported between various automotive sub-systems. Typically, each sensor or display unit has dedicated wiring running to its associated control unit. However, the proliferation of sensors and cameras in automotive systems leads to added cable weight and manufacturing costs for the wiring harness. At the same time, increasing resolution and frame rates for image capture and display require more bandwidth on each link. Meanwhile, OEMs are striving to reduce overall vehicle weight to meet fuel efficiency goals, which means new systems must manage the flow of data across the vehicle systems without adding more bulky wiring.

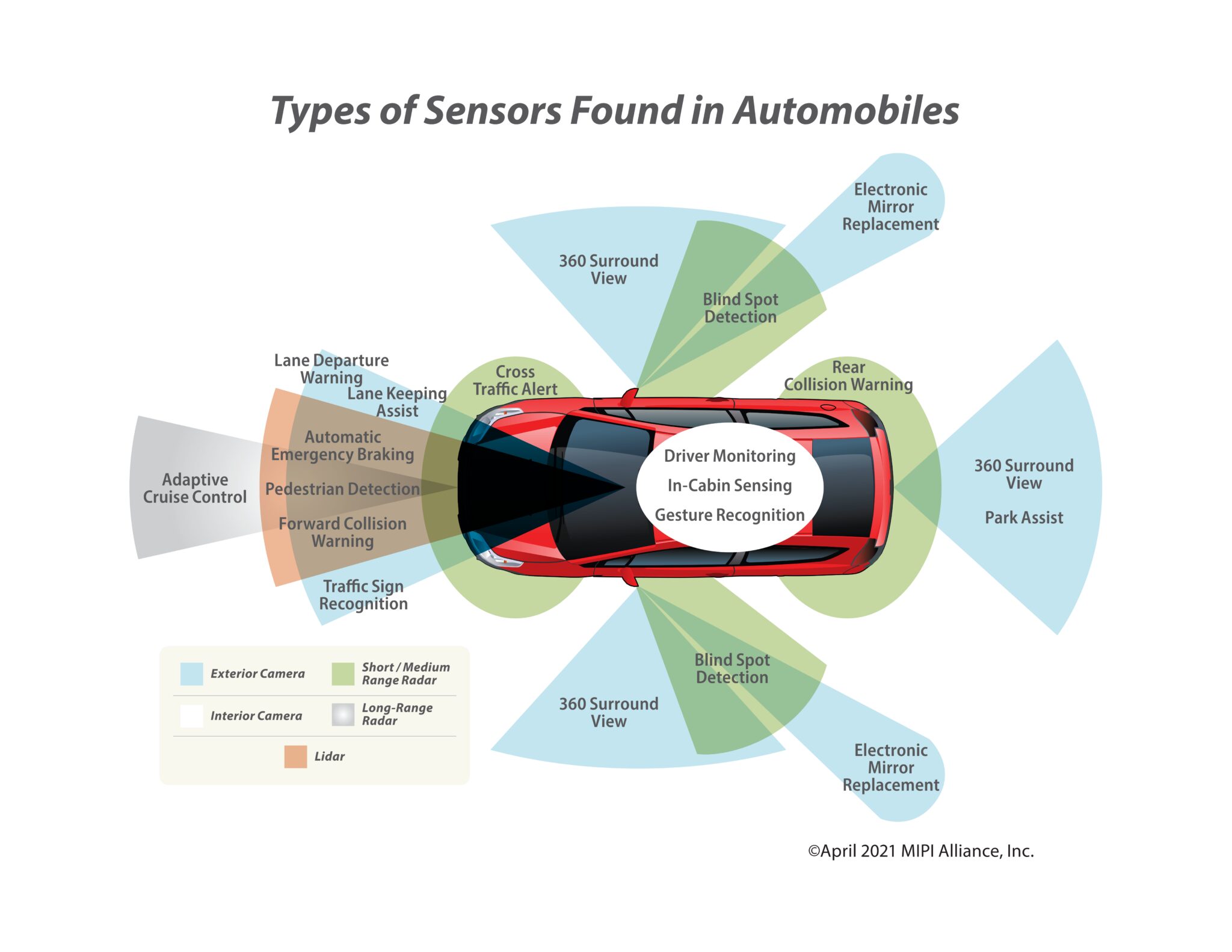

Sensors gather data front numerous points across the vehicle, requiring complex associated cabling to reach processing and video units. (Image courtesy of the MIPI Alliance.)

The Video Electronics Standards Association (VESA) oversees the standardization of streamlined and efficient connectivity solutions used with display technologies. VESA’s DisplayPort v2.0 standard (released in 2019) guides interface design for video and audio data in computers, portable devices, and automotive displays. DisplayPort uses packetized data transmission, permits the use of internal and external displays, carries audio and video simultaneously, and is capable of handling 8K content delivery. A DisplayPort connection consists of four lanes, each with a dedicated set of twisted-pair copper wires, to move a combined 77.4 gigabits per second.

An automotive version of DisplayPort 2.0 called Vehicular DisplayPort (VDP) which integrates elements of VESA’s embedded DisplayPort (eDP) standards, is currently in development. It will add vehicle-specific functions to the existing eDP standard. “As panel resolutions exceed full HD (1080p), the commonly used LVDS-based display interface is becoming impractical from a wire-count perspective. The increased data rates and reduced wire counts offered by DP and embedded DisplayPort (eDP), as well as other performance benefits enabled by these standards such as reduced power, video compression, and the ability to drive multiple displays from a single source, are attractive for higher-resolution automotive displays,” according to VESA’s Vehicular Taskforce Group (VTG).

All DisplayPort cables designs have the same basic layout and wiring, and will support audio, daisy-chaining, HDR, and DSC. DisplayPort specifies seven different transmission modes (RBR, HBR, HBR2, HBR3, UHBR 10, UHBR 13.5, and UHBR 20) which support progressively higher bandwidths. No specific cable length is dictated by VESA. DisplayPort cables and ports typically use a 20-pin single-orientation connector with a friction lock and an optional mechanical latch.

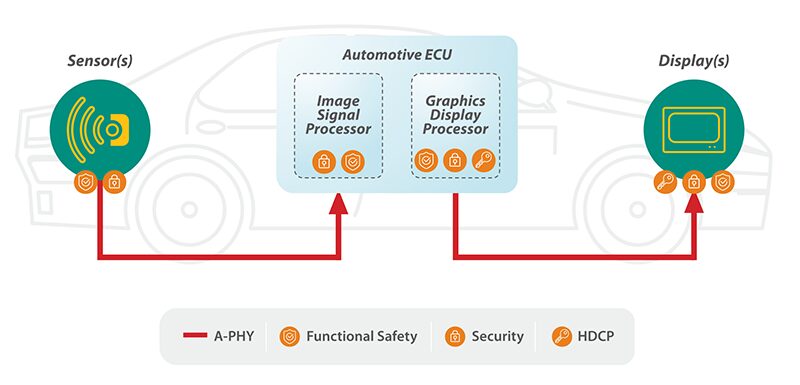

A centralized ECU processes data between sensors and displays.

MIPI Alliance offers additional guidance through its MIPI Automotive SerDes Solutions (MASS), a long-reach serializer-deserializer physical interface which allows OEMs to implement common automotive interface protocols across a vehicle over A-PHY. MASS help automakers integrate safety features such as low-latency backup cameras, lane-keeping and sign-detection sensors, and camera, lidar, and radar systems across shared wiring, compressing data to reduce the need for additional wiring. MASS also will support multiple high-resolution instrumentation, control, and entertainment displays. MIPI A-PHY, the first industry standard long-reach SerDes physical layer interface, forms the cornerstone of MASS. Its primary mission is to transfer high-speed data between cameras and displays and their control units. For OEMs, this simplifies networks and reduces costs, weight, and development time. A-PHY was also adopted as an IEEE standard in June 2021 and is available as IEEE 2977-2021.

EVAFLEX 5-VS connector by I-PEX supports 8 Gb/s high-speed signals and can be mounted to the same PCB layout as the VESA standard CABLINE VS receptacle.

Connector companies have worked closely with these standards bodies to develop products that support screen optimal functionality as well as OEM size, weight, reliability, electromagnetic compatibility, and ruggedness goals. Amphenol LTW, BizLink, Hirose Electric, and I-PEX Co. Ltd. are among the companies that offer MIPI, VESA, and automotive display solutions.

Hirose Electric’s DF9 connector is a VESA-certified 1mm pitch SMT board-to-board connector, available from Mouser Electronics.

Amphenol Socapex’s HDMI FTV connectors, available from Digi-Key Electronics, provide DisplayPort connectivity to vehicles used in harsh environments.

BizLink’s DP 4.1 Cable offers 8.1Gb/s per lane link rate and allows 5K monitors (5120 x 2880) with a single cable and no compression.

In the coming years, the automotive sector will tap into 5G infrastructure to enable enhanced connectivity through vehicle-to-vehicle (V2V) and vehicle-to-everything (V2X) technologies. Continued progress towards greater electrification and more autonomous functions will also place more demands on engineers to design efficient display architectures. As cable harnesses are among the most expensive, heavy, and expensive components in a vehicle, powerful, lightweight interconnects and standardized solutions will play a significant role in the design of automotive displays.

To learn more about the companies mentioned in this article, visit the Preferred Supplier pages for Amphenol LTW, BizLink, Digi-Key Electronics, Hirose Electric, I-PEX, and Mouser Electronics.

Like this article? Check out our other articles on Connected Vehicles and New Technology, our Automotive Market Page, and our 2022 Article Archive.

Subscribe to our weekly e-newsletters, follow us on LinkedIn, Twitter, and Facebook, and check out our eBook archives for more applicable, expert-informed connectivity content.

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024